Why Precision Machining Partnerships Are a Strategic Advantage for Automotive, Medical, and Heavy Machinery Manufacturers

In today’s fast-moving, quality-driven manufacturing landscape, companies in the automotive, medical, and heavy machinery sectors are under constant pressure to innovate, meet strict quality standards, and streamline production. A trusted precision machining partner isn’t just a vendor — they’re a strategic asset. Whether it’s producing intricate components with micron-level tolerances or scaling up production without sacrificing quality, the right partner can deliver unmatched value across your supply chain.

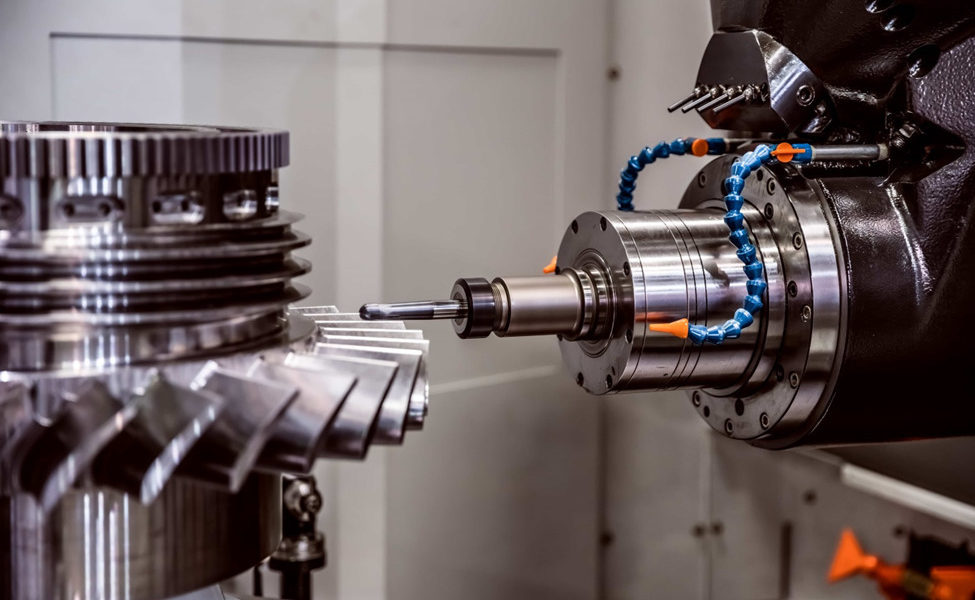

Precision Powers Performance

Tolerances Matter — Especially When Lives or Heavy Loads Are on the Line

- In the automotive industry, even the slightest deviation in a machined part can affect safety, efficiency, or emissions.

- For the medical field, components used in surgical tools or implants must meet exacting tolerances to pass FDA standards and ensure patient safety.

- Heavy machinery manufacturers rely on rugged, durable parts that can withstand extreme stress and perform consistently over time.

Your machining partner should have the equipment, experience, and quality control systems to consistently deliver precision — not just in prototyping, but throughout full-scale production.

Industry-Specific Expertise Reduces Risk

Understanding the Regulatory and Functional Demands of Your Sector

- Medical: ISO-certified processes, material traceability, and cleanroom packaging aren't optional — they’re expected.

- Automotive: TS/IATF compliance and lean manufacturing principles are key to meeting JIT (Just-In-Time) demands.

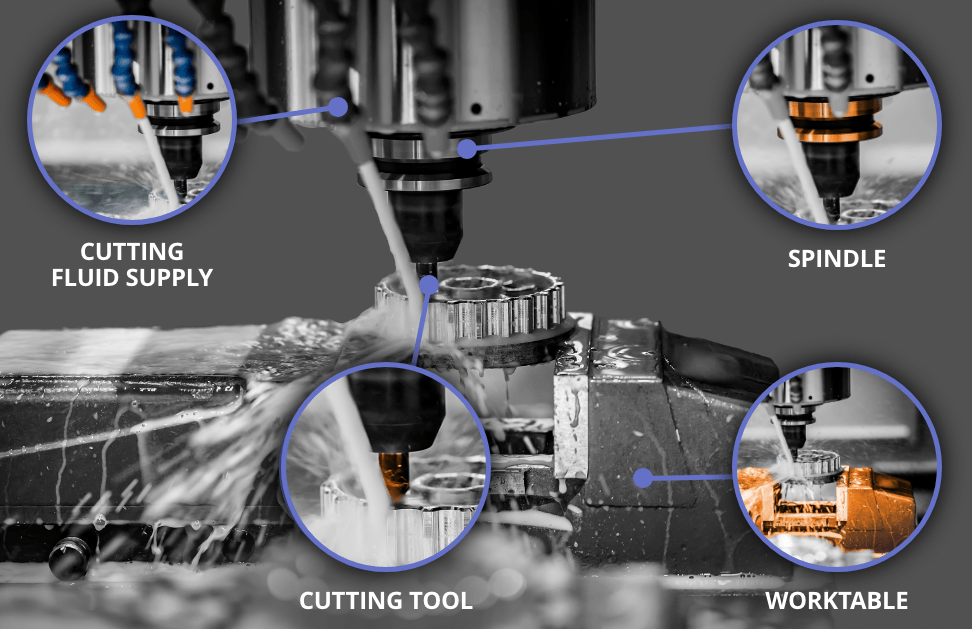

- Heavy Machinery: Larger, more complex parts require specific machining capabilities, from multi-axis turning to large-bore milling.

An experienced partner doesn’t need a learning curve. They’ve navigated these challenges before, and they build compliance into every step of the process — reducing your time to market and minimizing costly errors.

Agility, Scalability, and On-Time Delivery

More Than Machining — A True Manufacturing Extension of Your Team

When your partner understands your production goals, they can adapt quickly to design changes, volume shifts, or urgent deadlines. A high-performing machining partner offers:

- Swiss CNC capabilities for small, high-precision components

- Flexible production volumes, from prototyping to full-scale runs

- In-house engineering support to refine designs for manufacturability

- Responsive communication and reliable lead times to support tight schedules

Especially in industries where innovation cycles are getting shorter, the ability to ramp up or pivot quickly is a competitive advantage.

Long-Term Value Through Strategic Collaboration

Beyond Components — Building Better Products Together

The best machining relationships evolve into collaborative partnerships. Your machining partner should offer insights to improve your product designs, reduce material waste, and cut production costs — all while maintaining top-tier quality.

At Hi-Standard Machining, we work closely with engineering and procurement teams to create components that are not just manufacturable but optimized for performance and longevity. It’s about delivering precision, efficiency, and peace of mind, no matter your industry.

Invest in a Machining Partner, Not Just a Vendor

In the automotive, medical, and heavy machinery sectors, the quality of your components impacts everything from safety to brand reputation. Don’t leave it to chance. A machining partner like Hi-Standard brings the expertise, equipment, and reliability you need to drive success — today and into the future.

Contact us to learn how we can support your next project with unmatched precision and partnership.